High quality, low cost, and fast delivery have become urgent needs of the industrial chain's upstream and downstream. As the core equipment for the construction of smart logistics, mobile robots are the first to reduce costs, maintain quality, and improve efficiency.

At the core of the mobile robot supply chain, for many years, Kinco has focused on robot walking power. In line with the development trend of robot integration, miniaturization and lightweight, it has taken the lead in launching the iWMC series servo wheel walking power module that integrates drive, motor, reducer and wheel, and is committed to creating a standardized mobile robot chassis to break a series of cost reduction difficulties caused by long-term customization.

With high expectations, Kinco's first iWMC servo wheel was launched at the end of 2022. It is aimed at 600kg medium-load mobile robots. With its highly integrated component design, it not only reduces the client's mechanical design complexity but also saves installation space by 30%+, reduces installation hours by 80%+, greatly improves maintenance difficulty and efficiency, and significantly reduces the comprehensive use cost. It received a warm response once it was launched.

Only 18 months after its launch, the replacement rate of the old and new solutions for 600kg models has steadily increased, and the application rate of iWMC integrated power solutions for new machines has reached 60%+, with a cumulative shipment volume of tens of thousands of units, which clients have widely recognized.

Success is inevitable, but the speed is somewhat beyond expectations, which further strengthened Kinco's perception: integration is the trend, and extreme integration is urgently needed.

Within a year, the 600kg model has been successfully applied to multiple terminal scenarios such as photovoltaics, lithium batteries, 3C, automobiles, tobacco, packaging, etc. Over time, we have received continuous demand from customers for products with multiple load specifications, covering a wide range from 10kg to 10tons. If the 600kg servo wheel represents our innovative breakthrough from 0 to 1, then the expansion from 1 to N is the natural next step for Kinco.

Although medium and large load models pose greater challenges to integrated products due to their complex structure, high technical difficulty, and more stringent application conditions, the Kinco team rose to the challenge. During the development process, we faced a series of difficulties to ensure key performance such as efficiency, stability and balance. However, through unremitting efforts, we have overcome these difficulties one by one from drive algorithms to reducer adaptation to the construction of process production lines.

Now, we are proud to launch the new iWMC integrated servo wheel - a power integration solution designed for 1T load models. Not only flexible and simple, it also comprehensively reduces costs.

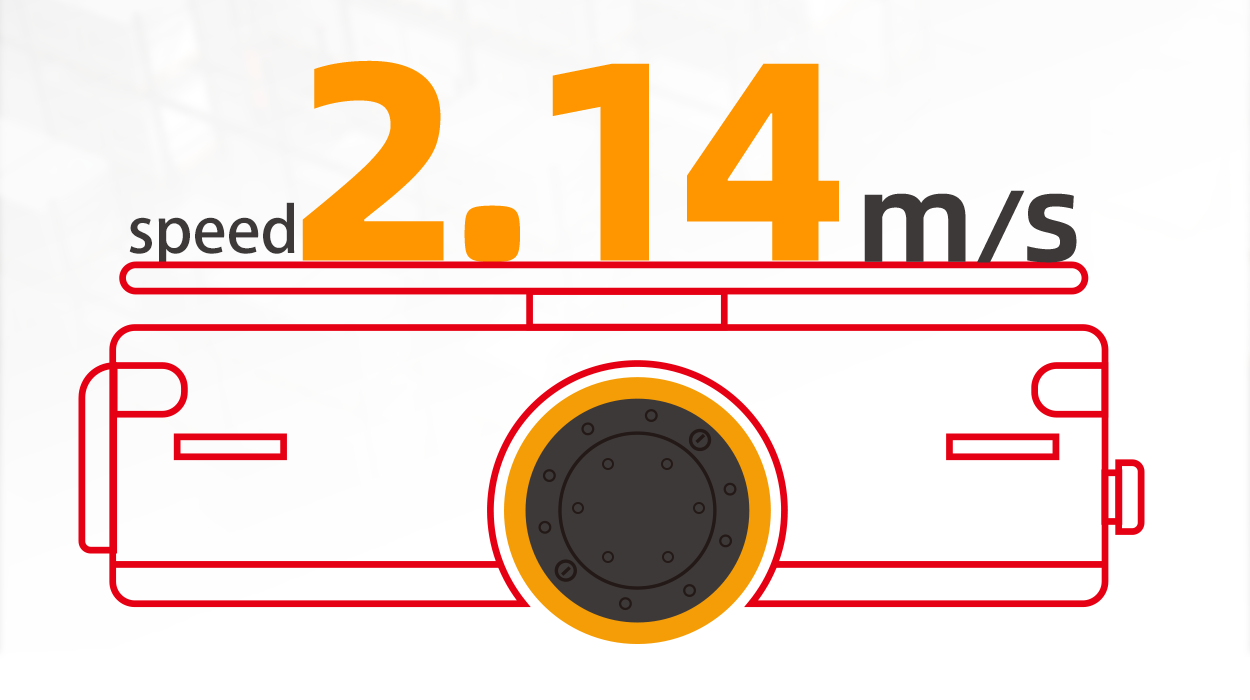

FAST SPEED

Improved vehicle efficiency, more competitive

STRONG POWER

Faster full-load starting speed, and stronger climbing and obstacle-crossing capability

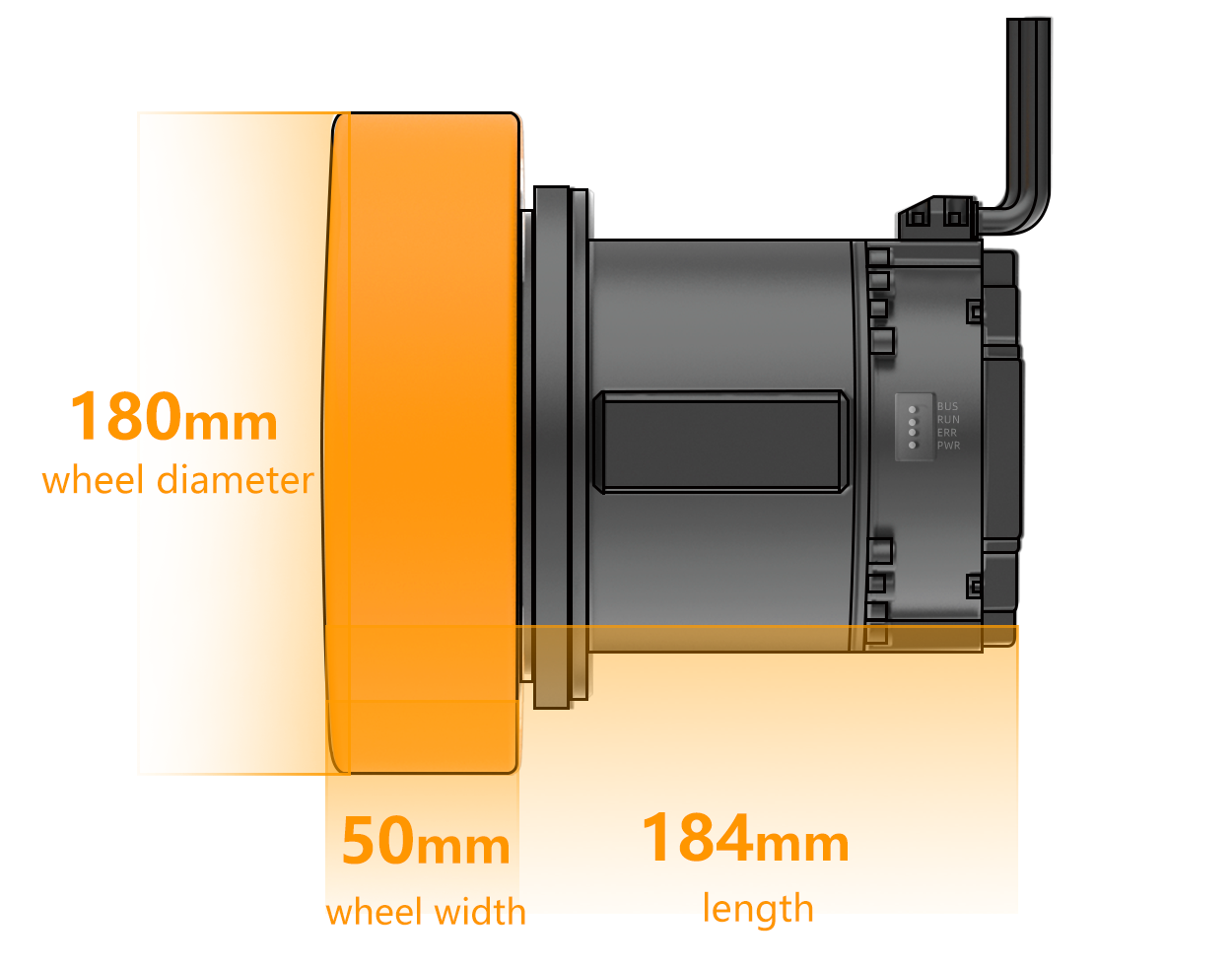

OPTIMIZED DESIGN

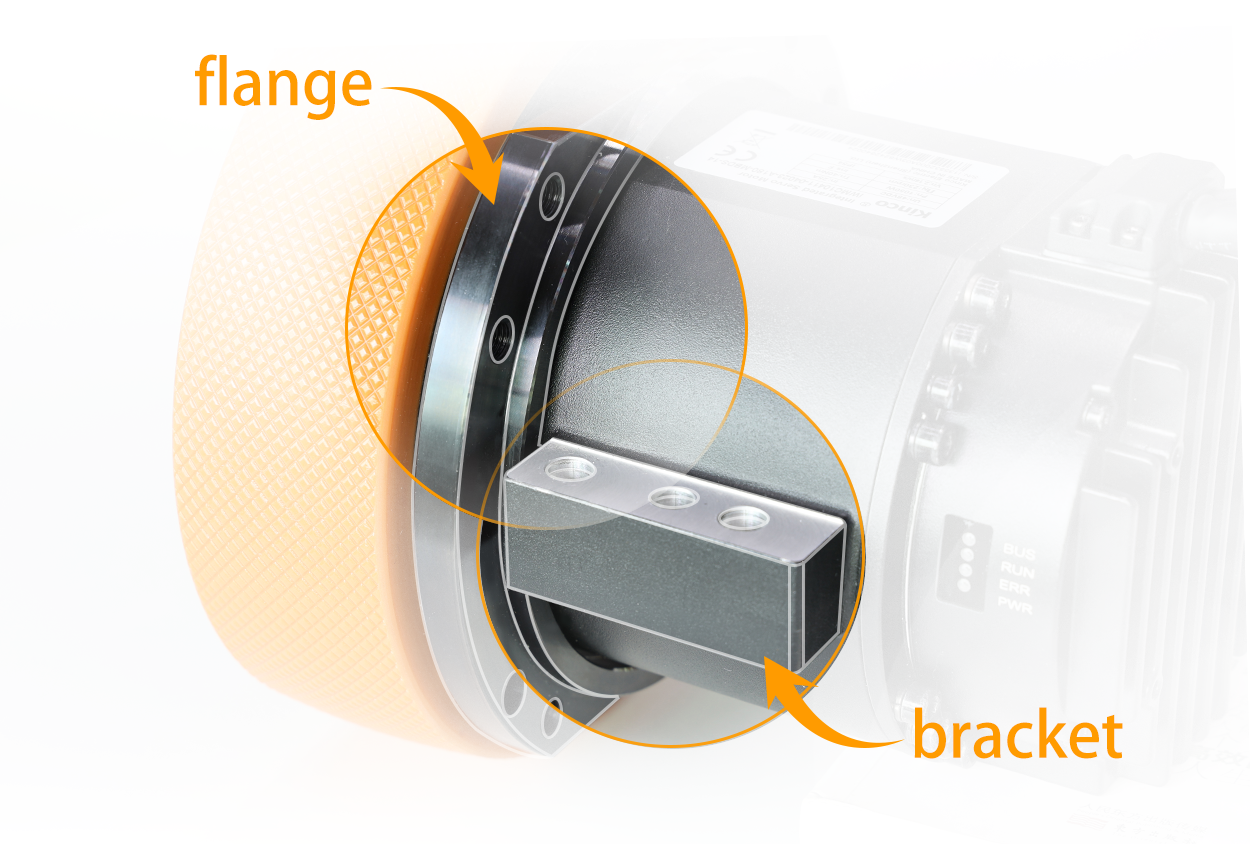

Ultimate integrated design helps build compact equipment

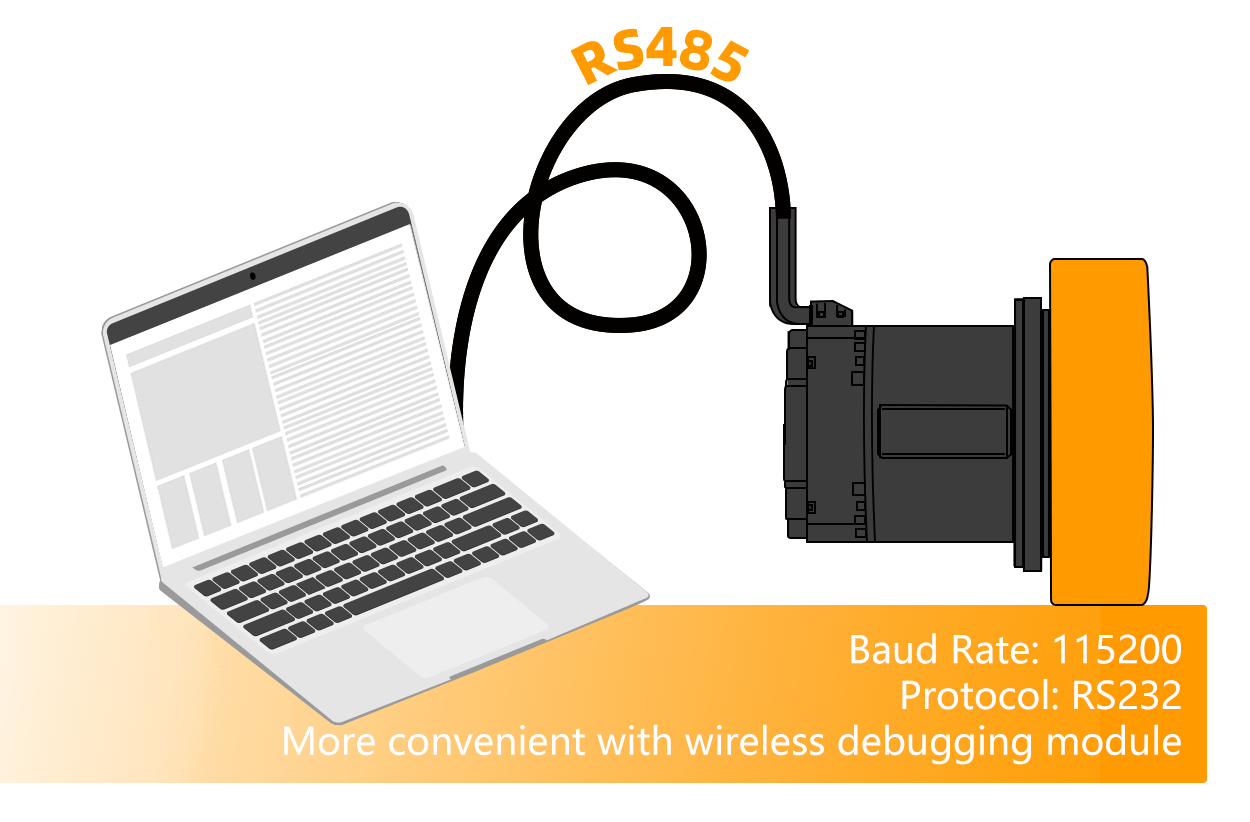

SIMPLIFIED DEBUGGING

RS485 communication, debugging with only a cable

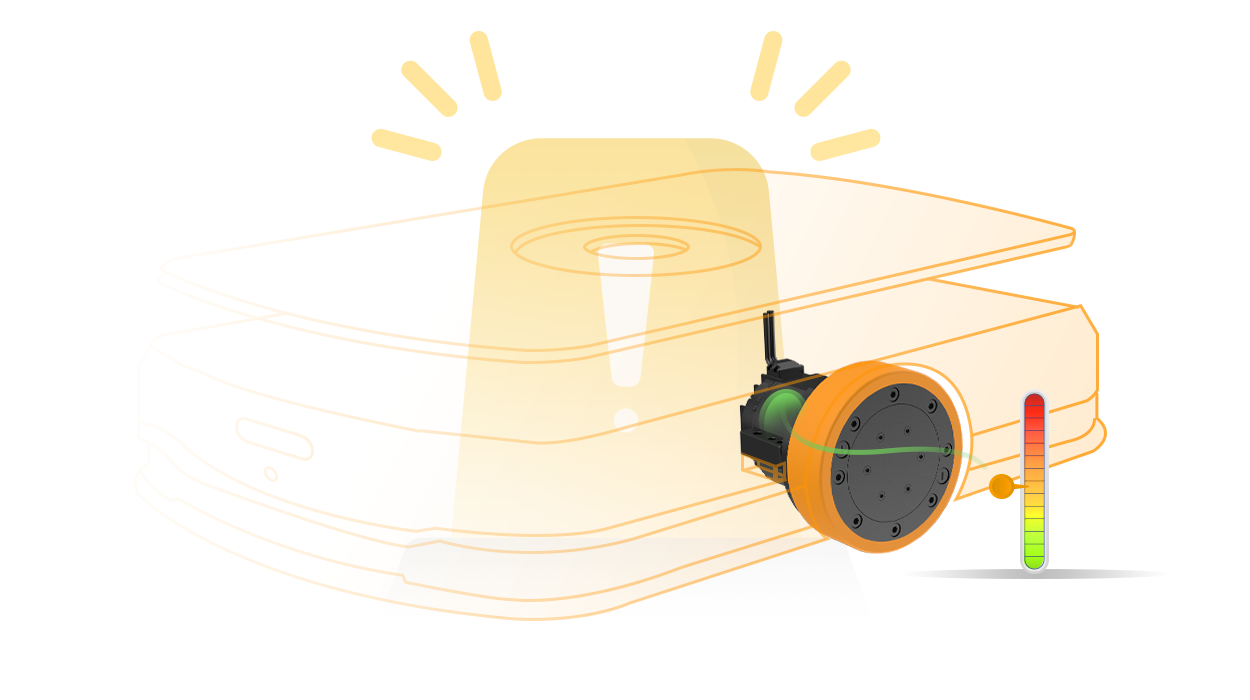

SAFETY FIRST

Built-in temperature sensor to monitor the internal temperature of the servo wheel

Beforehand temperature abnormality warning to ensure safe operation of AGV

FLEXIBLE INSTALLATION

2 installation methods to cover more chassis structures

COMPLETE CERTIFICATION

With CE and UL certifications

More specifications 50kg, 300kg, 1.5T... will be launched in succession to meet the integrated walking power needs of mobile robots in various scenarios. STAY TUNED!

© Kinco Electric (Shenzhen) Ltd.